We specialize in providing tailored automation solutions for a wide range of industries. Whether you're looking to enhance efficiency, improve precision, or reduce operational costs, Moldbetter has you covered.

Explore servicesElemch Automations develops, constructs, and supplies factory automation systems designed to help you produce and test components and products more efficiently than ever before.

We manufacture automation machines ranging from modular assembly cells to fully-automated assembly lines. We also build automated testing/inspection equipment including custom-integrated testing systems, stand-alone automatic test systems, and manual test benches.

Our automation systems fully integrate with production equipment in a wide range of manufacturing facilities ranging from automotive factories to clean rooms. Elmech technology products with other assembly equipment and testing/inspection systems to help streamline manufacturing processes.

The objective is always the efficient solution of a complex assembly problem. The challenge for us is therefore to use our extensive know-how and experience to develop solutions which will enable our customers to manufacture their product in an economical manner.

We spare no expense to fully understand the nuances of your product development lifecycle, your existing assembly equipment, and your overarching production goals. This enables us to design the perfect automated manufacturing solution to help you achieve your objectives and provide you with an impressive return on investment.

Every factory automation system we design, build, and implement strictly adheres to lean manufacturing principles. Regardless of your specific manufacturing operation, we can help you reduce inefficiencies, floor space, and production time while increasing your production capacity and profitability.

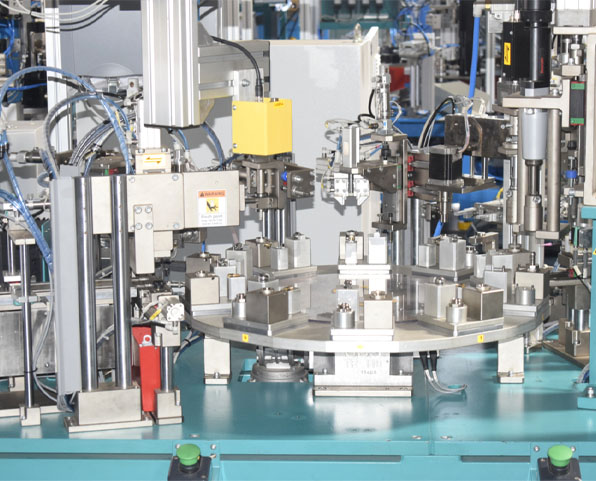

Beyond manufacturing systems, we are deeply versed in rotary assembly lines using Globoid Cam Indexers and motion control. We link production equipment, material handling systems, data collection, networking, and computer software and hardware into flexible, fully-automated solutions. With over 10 years of experience in automation engineering – and a 98% on-time delivery record over that period – you can be sure that no product assembly challenge or pain point is too large for us to streamline

Elmech Automations designs and builds custom assembly systems to help manufacturers reach their full factory production potential.

We manufacture flexible, lean assembly equipment — ranging from manual workstations to fully-automated, turnkey assembly lines — that allow you to increase assembly process efficiency and profitability and improve product quality and safety.

Whether with a simple workstation or fully-automated assembly system, Elmech Automations technology reflects the utmost precision in robotics design, construction, and integration. It always aims at maximum process reliability and our objective is always the efficient solution of a complex assembly problem.

For our customers this means maximum modularity and flexibility in their assembly automation systems – accompanied at the same time by a high level of availability and re-useability. Elmech Automations assembly machines can always be adapted to new product versions or changing product life cycles.

We spare no expense to fully understand the nuances of your product development lifecycle, your existing assembly equipment, and your overarching production goals. This enables us to design the perfect automated manufacturing solution to help you achieve your objectives and provide you with an impressive return on investment.

Depending on the job in question, our systems deal with small and miniature parts at high output rates or heavy parts with a low output rates. A long working life and precision are the cornerstones of Elmech Automations assembly systems. We follow a very clear principle to never compromise on the quality and availability of the assembly plant and equipment which our team manufactures and delivers. This is our contribution to the continued corporate success of our customers.

Our in-house team of engineers and tradesmen work closely with customers to satisfy their requirements—from consultation and design to install, start-up and training. We immerse ourselves in product development, design, and product launch procedures and analyze all production steps thoroughly. We delve deeply into the processes of manufacturing a product before we offer a solution.

Elmech assembly systems are designed not only with design, structure and economic factors in mind — they also always take account of the return on investment over the entire life cycle of a machine.

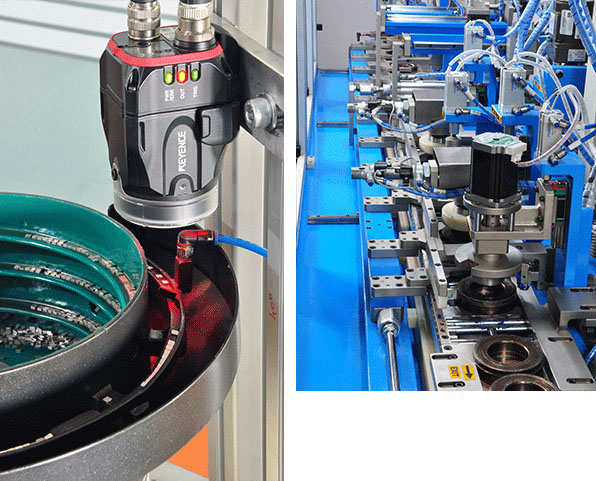

Product – 1200 RPM Spinning Spindle bearing assembly – 14 Component Automatic Feeding and assembly at a cycle time of 5 seconds per assembly.

Product – Rocker Arm Needle roller Bearing Assembly – Assembly and Vision based inspection of assembled product at a cycle time of 3 seconds per assembly.

Elmech Automations builds automated test systems designed to help you solve your most difficult testing challenges, such as component performance testing, functional testing, conformance testing, destructive testing, dimensional testing, leak and flow testing, and more.

We specialize in testing electrical, mechanical, hydraulic, and pneumatic components, as well as actuation systems.

Whether we design your next fully-integrated test system, stand-alone automatic test system, or manual test benches, every test solution is custom-built to improve testing process efficiency.

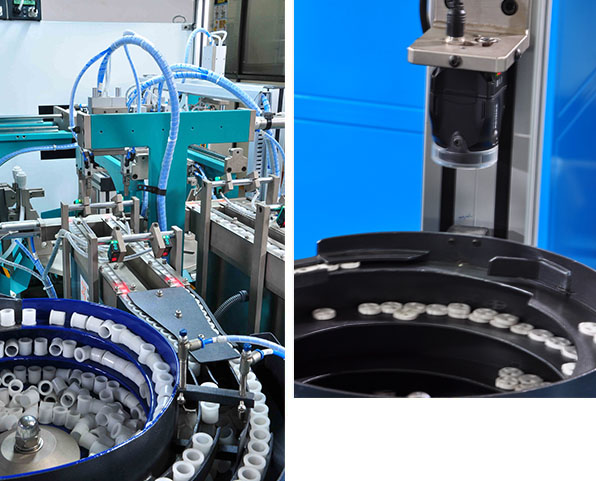

Our Industry-Leading Part Feeders Offer Efficiency and Reliability

Elmech Automation designs and builds standard and specialty part feeders for virtually every type of part or application. For more than 5 years, we’ve been manufacturing equipment unequaled in reliability and efficiency. Equipment includes a full line of reliable systems from fully automated feeders to our exclusive escapement devices and portable, hand-held screw feeders.

We design our feeder equipment to be easy to maintain and the most dependable in the industry ¬– outlasting the production runs they service. Our trouble-free feeding systems reduce the cost of assembly and eliminate the chance of damage to both the parts being fed and the application itself. It is our careful attention to detail that makes ELMECH Auto feeding systems are the industry’s preferred feeding systems.